Product successfully added to your shopping cart

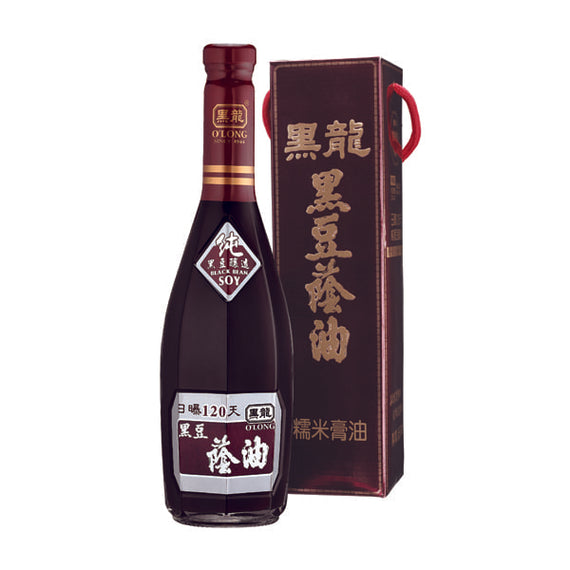

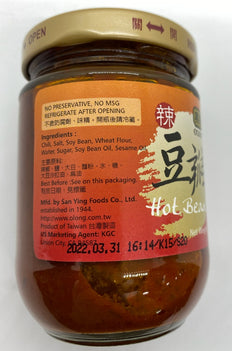

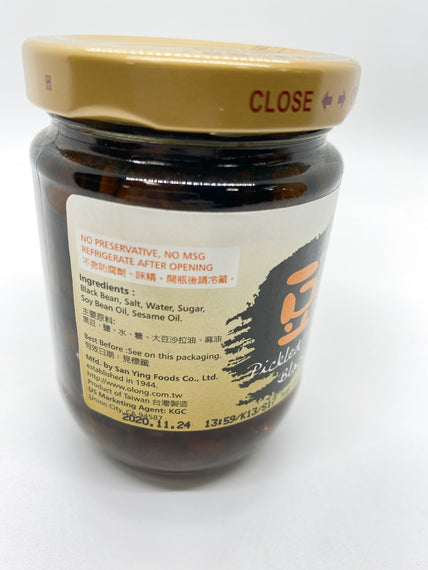

O'LONG Gift Box Superior Black Bean Soy Sauce (Thick) 黑龍 特級黑豆蔭油(膏油)禮盒裝 600ML

The Artisan's Craft: How 膏油 (Thick Soy Sauce) Is Made

Understanding the production of 膏油 (Gāo Yóu) reveals why it possesses its unique characteristics of color, viscosity, and complex sweetness. It's not merely thickened light soy sauce, but the product of a deliberate, often extended, transformative process.

The Foundational Journey: From Bean to Soy Sauce

First, it's crucial to understand that 膏油 starts its life as 清油 (Light Soy Sauce). The universal first steps are:

-

Koji Cultivation: Soybeans (and usually roasted wheat) are inoculated with the mold Aspergillus oryzae. This creates "koji," a mold-cultured grain that is the engine of fermentation.

-

Brine Fermentation: The koji is mixed with a saline brine in large fermentation vats (traditionally ceramic urns or wooden barrels). Here, a slow fermentation—taking from several months to years—breaks down proteins and starches into amino acids (umami), simple sugars, and other flavor compounds. This creates raw soy mash, or moromi.

-

Pressing & First Extraction: The moromi is pressed. The first liquid that flows out, often under its own weight, is the most refined, aromatic, and balanced. This is Premium Light Soy Sauce (生抽).

The Specific Transformation into 膏油 (Thick Soy Sauce)

Here is where the paths diverge. To create 膏油, producers take light soy sauce and subject it to further processing. There are two primary traditional methods:

Method 1: The Extended Aging & Concentration Method (Traditional)

This is the artisanal approach, prized for depth of flavor.

-

Extended Aging: The light soy sauce is returned to barrels and aged for an additional several months to years. During this prolonged aging, oxidation and continued enzymatic reactions mellow the sharp saltiness and develop richer, deeper, almost caramel-like flavors.

-

Natural Concentration: Through evaporation over time, the sauce naturally becomes slightly more concentrated.

-

Addition of "Caramel" (糖色 - Táng Shǎi): A small amount of maltose (麦芽糖) or caramelized sugar is often blended in. This is not "caramel" as in candy, but a traditional Chinese cooking sugar deeply heated until it becomes a complex, slightly bitter, reddish-black syrup. This adds the characteristic dark color, a touch of sweetness to balance the salt, and a glossy finish.

Method 2: The Finishing & Thickening Method (Common Commercial)

This method standardizes the product for consistency and is more common today.

-

Base Sauce: A batch of regular light soy sauce (often a later pressing of the moromi, which is less delicate) is selected as the base.

-

Sweetening & Coloring: Caramel color (E150d)—a food-safe, standardized version of táng shǎi—and sometimes molasses, sugar, or licorice root are added for sweetness and the definitive dark brown-black hue.

-

Thickening: A small amount of a starch slurry (commonly from wheat or tapioca) is introduced. The mixture is gently heated, causing the starch to gelatinize and give the sauce its signature slightly sticky, clingy viscosity that coats a spoon.

-

Final Pasteurization & Blending: The sauce is pasteurized to stop fermentation and ensure shelf stability, then blended for uniformity before bottling.

Key Additives & Their Roles in 膏油

-

Caramel (糖色 or E150d): The primary colorant. Provides the deep black-brown tone and a hint of toasty sweetness.

-

Starch (Wheat, Tapioca): The primary thickener. Creates the viscous, glaze-like texture that distinguishes it from light soy sauce.

-

Maltose / Molasses: Enhance the sweet, rounded profile, balancing the residual saltiness and adding body.

-

Extended Aging: The primary flavor developer in traditional versions. Creates mellow, umami-rich, layered flavors without harshness.

The "Second-Press" Tradition

In some artisanal contexts, 膏油 is made from what's called a "second-press" soy sauce. After the premium first extract (light soy sauce) is taken, water is added back to the moromi, which is then repressed. This less salty, more robust extract becomes the perfect base for further aging and transformation into thick soy sauce, as it can better withstand and benefit from the prolonged processing.

The Culinary Alchemy: What the Process Achieves

-

Color Transformation: The addition of caramel and extended aging turns the amber-brown of light soy into a deep, reddish black.

-

Flavor Mellowing: The sharp, salty front of light soy is subdued. The flavor profile shifts from "salty, then umami" to "sweet & malty, then deep umami, with a faint salty finish."

-

Physical Texture: The starch creates a clingy, glaze-forming viscosity that is essential for coating noodles and adhering to the surface of braised meats, creating that lacquered look.

In essence, 膏油 is a finished product designed for specific culinary functions—coloring and glazing—whereas 清油 is a primary seasoning. Its creation is a conscious act of culinary engineering, whether through the slow patience of traditional aging or the precise application of modern food science. Knowing this process helps explain why a single teaspoon can so dramatically alter the appearance and depth of a dish

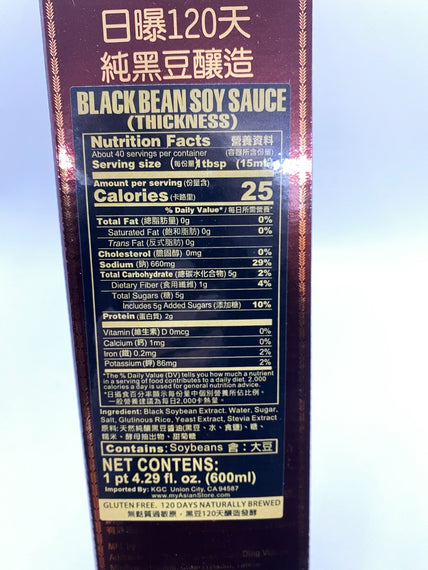

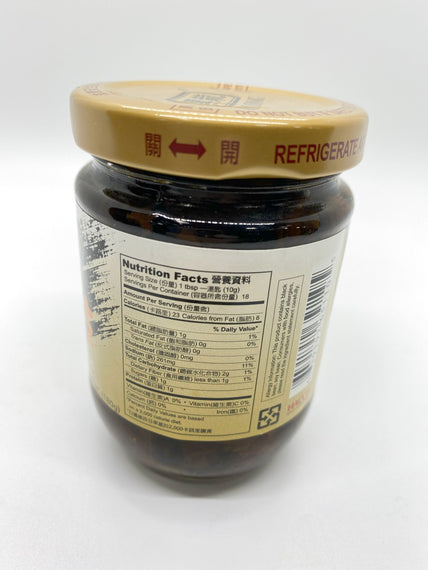

Net Weight: 600 ML

Country of Origin: Taiwan

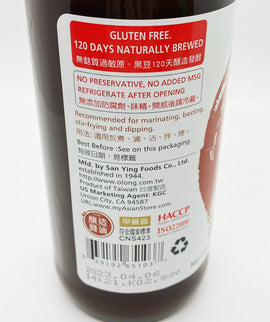

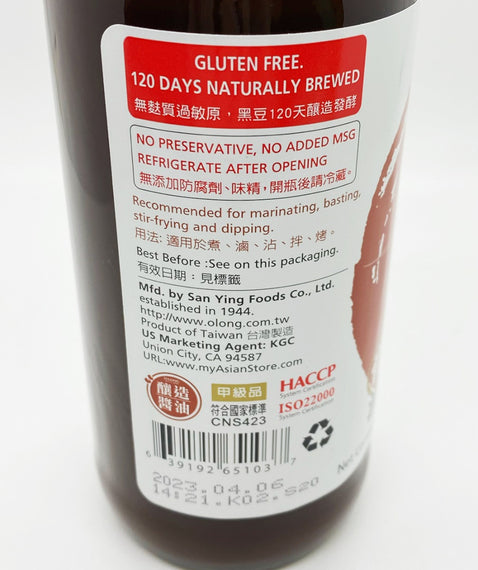

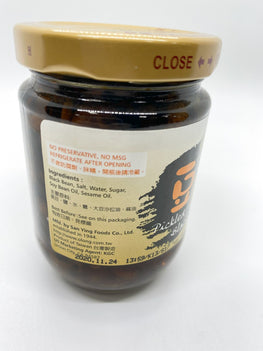

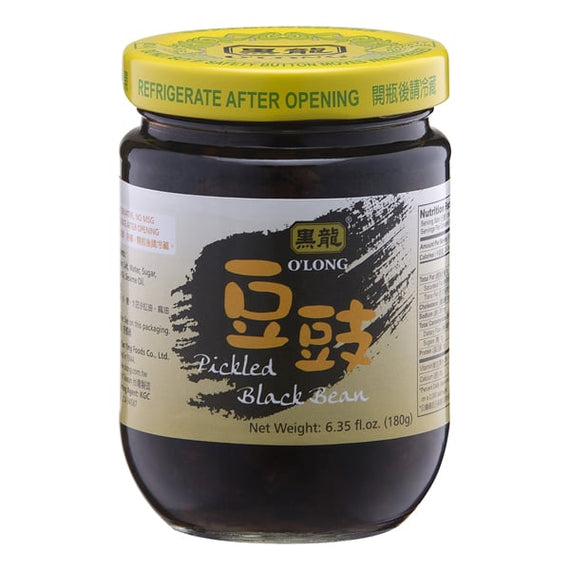

About O'LONG

San Ying Foods co., Ltd. Is the parent company of O’LONG and was founded in 1944. For more than 60 years, it has been one of the most experienced and well-known soy sauce manufacturers in Taiwan. San Ying Foods follows Chinese home-made recipes to ferment black soybeans for their various products and achieve the extraordinary black bean soy sauce taste that consumers look for. Even as the facilities move towards modern methods, San Ying Foods still strongly insists on the principle of following the traditional processes of a 120-day sun exposure and natural brewing to maintain the original and particular flavor of soy sauce and absolutely no preservatives, MSG, saccharin or pigment to maintain body health and nutrition of their consumers. San Ying Foods is committed to produce and sell safe, healthy and nutritious food to the public.